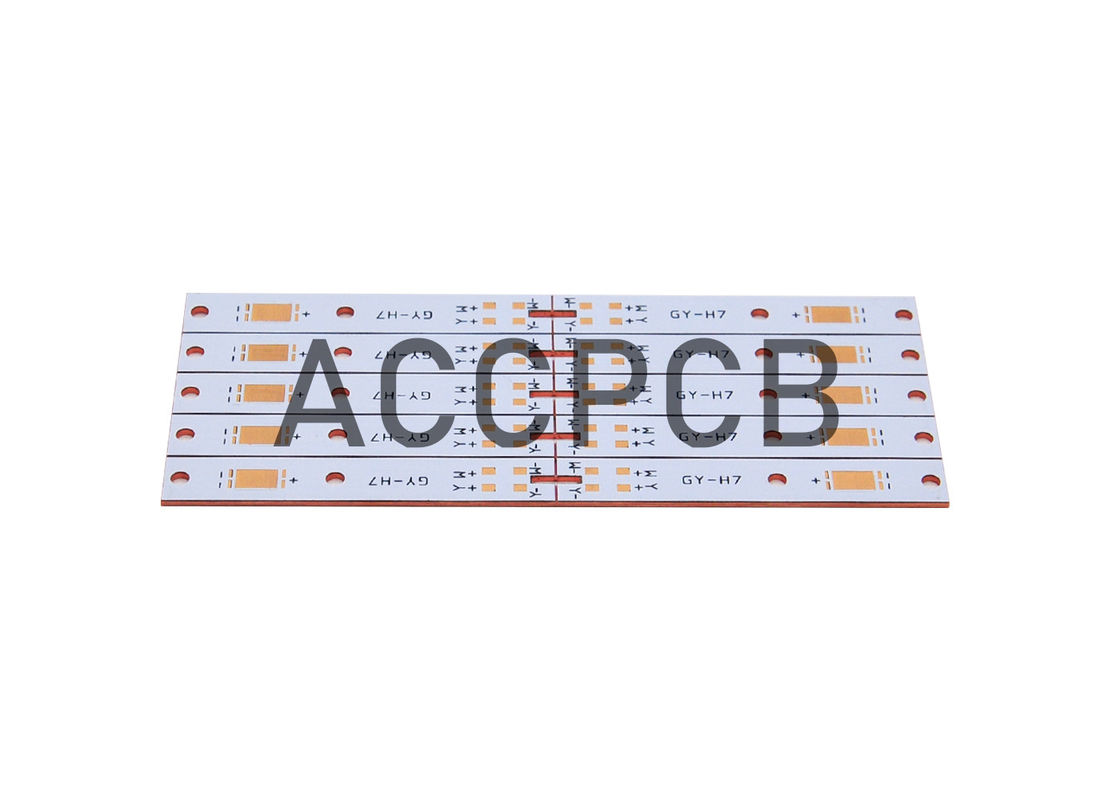

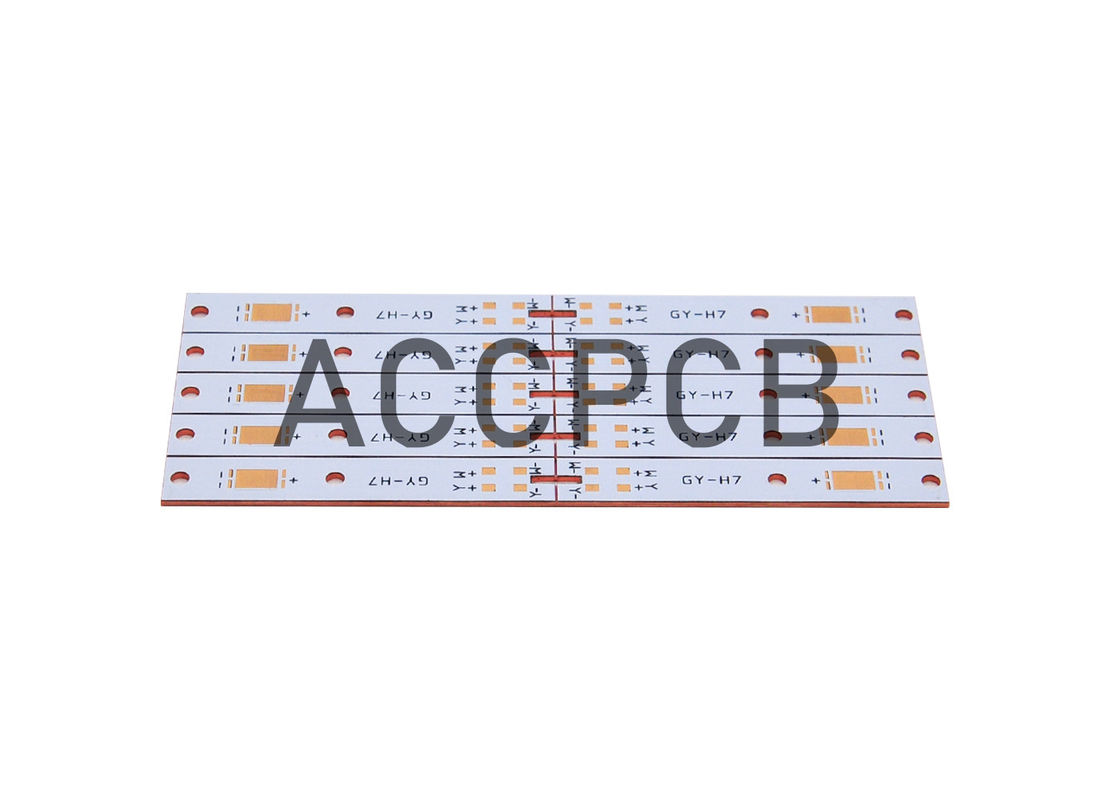

Aluminum Substrate LED light PCB with with solder mask for Tri - Proof Purification Lamp

Key Specifications/Special Features:

| Base material : | Aluminum Substrate |

| Copper thickness : | 2 oz in all layer |

| Board thickness : | 1.6 mm |

| Min. hole size : | 0.25mm |

| Min. line width : | 8 mils |

| Min. line spacing : | 8 mils |

| Surface finishing : | lead free HAL |

| Application : | Tri-proof Lamp Purification Lamp |

| Thermal Conductivity : | 2.50w/m·k |

| Board thickness tolerance : | ±10% |

| Twist& wrap : | ≤ 0.5% |

| Certificate : | RoHS, ISO 9001, UL |

| Support : | OEM |

Full range of testing services:

▪ AOI, function testing, In circuit testing, X-ray for BGA testing

▪ 3D paste thickness test

▪ Flash testing and earth bonding tests can also be undertaken where required

▪ Using our X-ray machine, we test PCBs to component level and all wiring is fully inspected and tested

▪ Each board is carefully examined by our dedicated inspection team using AOI and high magnification viewers

Products Application:

1, Consumer Electronics: TV, DVD,Digital Caramer, air conditoner, Refrigerator,set-top box etc;

2, Security monitor: Moible phone, PDA, GPS, caramer monitor etc;

3, Telecom Communication :wireless LAN card, XDSL router,Servers, Optical Device,Hard Drive etc;

4, Industrial controls: Medical device ,UPS equipment, Control device etc;

5, Vehicle Electronices: Car etc;

6, Military & Defense : Military Weapons etc;

Tecjnology Capability:

| Item | Technical Parameters |

| Layers | 1-28 Layers |

| Inner Layer Min Trace/Space | 4/4 mil |

| Out Layer Min Trace,Space | 4/4 mil |

| Inner Layer Max Copper | 4 OZ |

| Out Layer Max Copper | 4 OZ |

| Inner Layer Min Copper | 1/3 oz |

| Out Layer Min Copper | 1/3 oz |

| Min hole size | 0.15 mm |

| Max.board thickness | 6 mm |

| Min.board thickness | 0.2mm |

| Max.board size | 680*1200 mm |

| PTH Tolerance | +/-0.075mm |

| NPTH Tolerance | +/-0.05mm |

| Countersink Tolerance | +/-0.15mm |

| Board Thickness Tolerance | +/-10% |

| Min BGA | 7mil |

| Min SMT | 7*10 mil |

| Solder mask bridge | 4 mil |

| Solder mask color | White,black,blue,green,yellow,red,etc |

| Legend color | White,black,yellow,gray,etc |

| Surface finish | HAL,OSP, Immersion Ni/Au ,Imm silver/SN,ENIG |

| Board materials | FR-4;high TG;HighCTI; halogen free; Aluminum Bsed PCB,high frequency(rogers,isola),copper -base PCB |

| Impedance control | +/-10% |

| Bow and twist | ≤0.5 |

FAQ:

1. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

2. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

3. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

4. How many types of surface finish ACCPCB can do?

the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

Any further question, welcome to contact us by sending your inquiries

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!