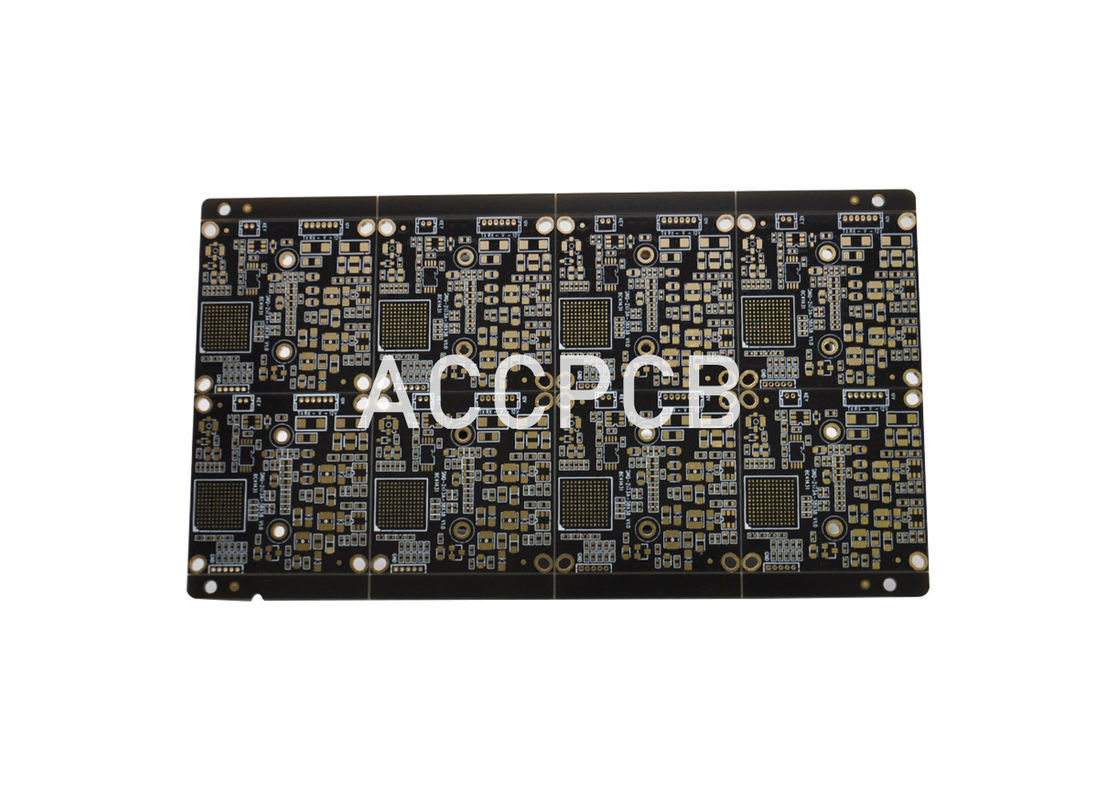

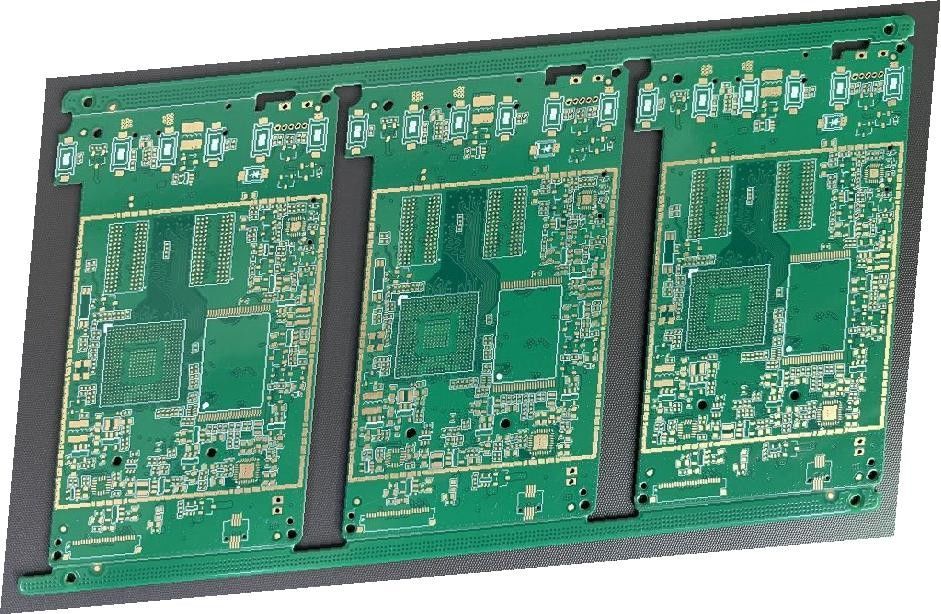

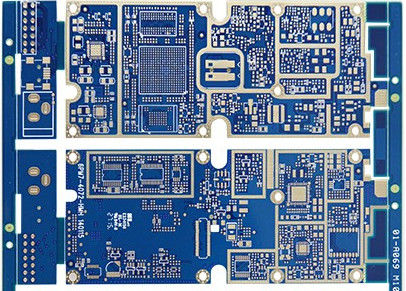

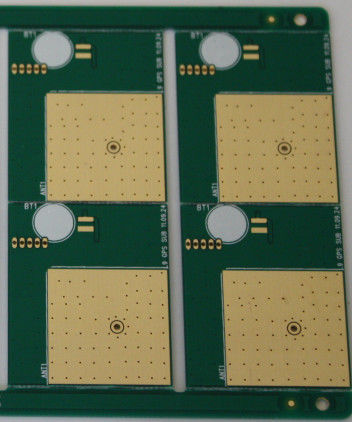

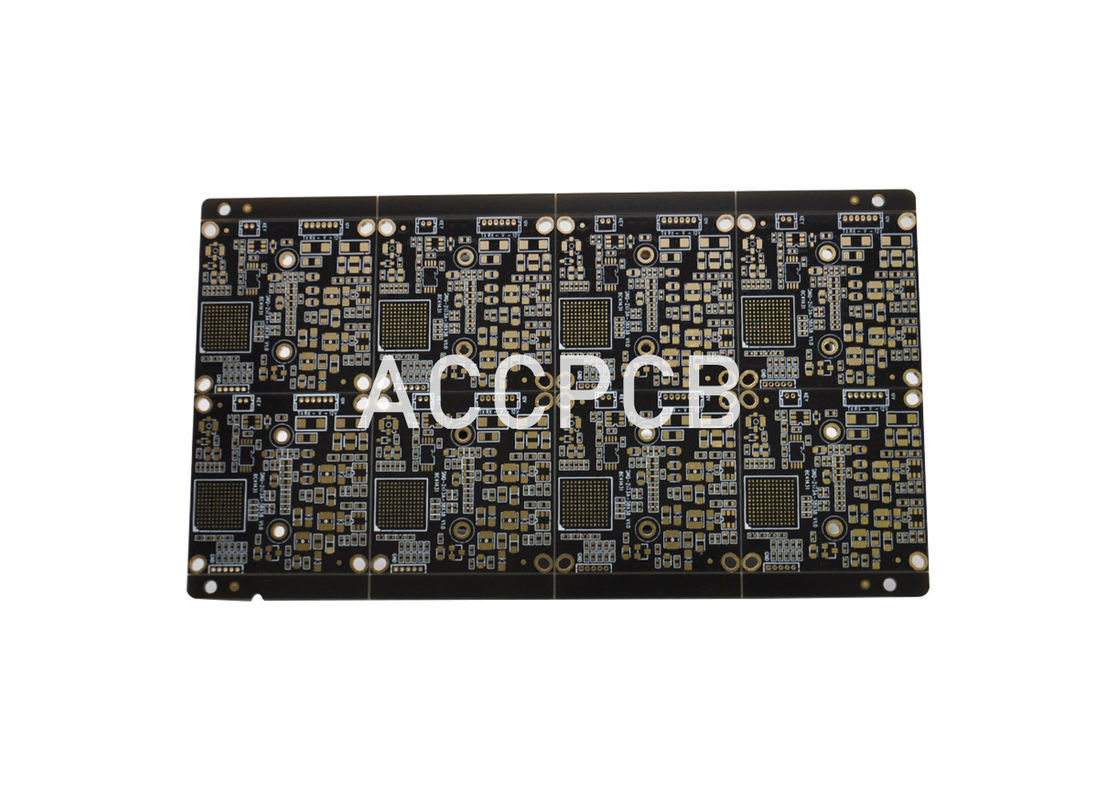

FR4 TG170 PWB Printed Wiring Board Black Oil For Security Monitoring Equipment

Production description :

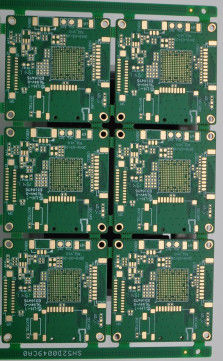

this board is 8layer with 2oz copper thickness. it is used for monitor equipment. we can accept any quantity board such as PCB prototype,samll volum, middle and large volume . no MOQ request for new order. all of these boards are met UL,TS16949, ISO9001 Etc.

Key Specifications/Special Features:

| Layer count : |

8 layer

|

| Finish thickness: |

1.2 ±10%mm

|

| Minimum width/spacing: |

0.1/0.1mm |

|

Minimum via dia :

|

0.1mm |

| Surface finish: |

ENIG

|

| Specialty: |

L1-2, L2-3, L4-5

|

| L2-5: |

Buried vias resin filled |

| L1: |

differential impedance of 100±9Ω

|

| Outline: |

Routing,V-Groove, Beveling punch |

| Company type: |

Manufacturer/ Factory |

Here is our PCB order capability:

- Layer : up to 20 layers

- Materials : FR-4, FR4 High Tg/ High CTI Material

- TG : 130-170

- Surface : HASL LF , Immersion Gold/Silver/Tin, OSP, Gold Plated

- Min drill size : 0.10mm

- Min track/spacing : 4/4-mil

- Buried and blind via : 0.2mm

- CNC Milling and V-cut

- Solder mask colors : Green, Blue, Black, White, Red and Yellow, Matte green, Matte black, Matte Blue

- Silkscreen colors : black, white and yellow

- Half Holes

- Impedance control

- Blue Peelable Mask

- Carbon Treated

- HDI available

FAQ :

1. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

2. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

3. What’s the typical process flow for multi-layer PCB?

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond→ Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.

4. How many types of surface finish ACCPCB can do?

O-the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!