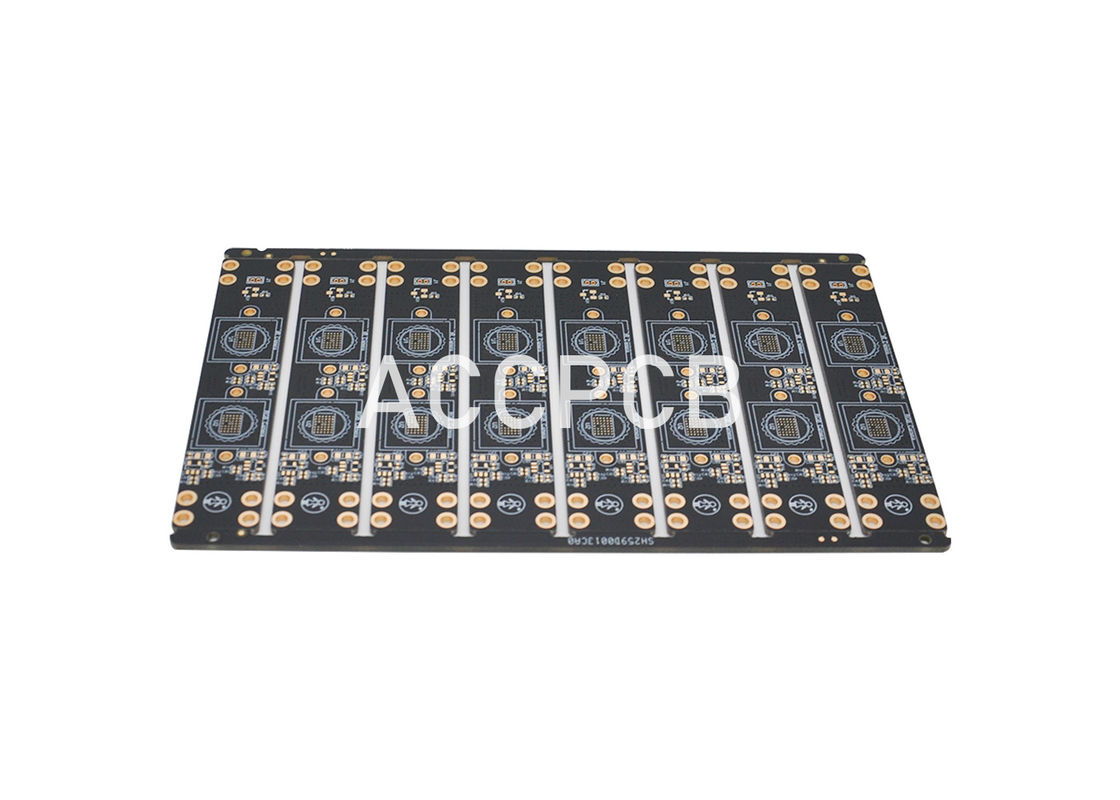

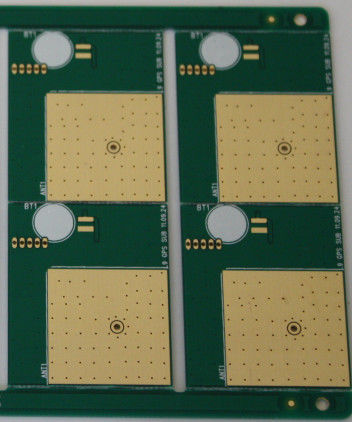

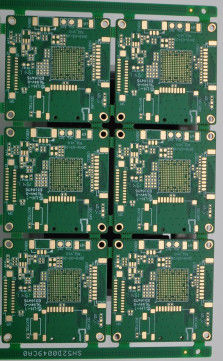

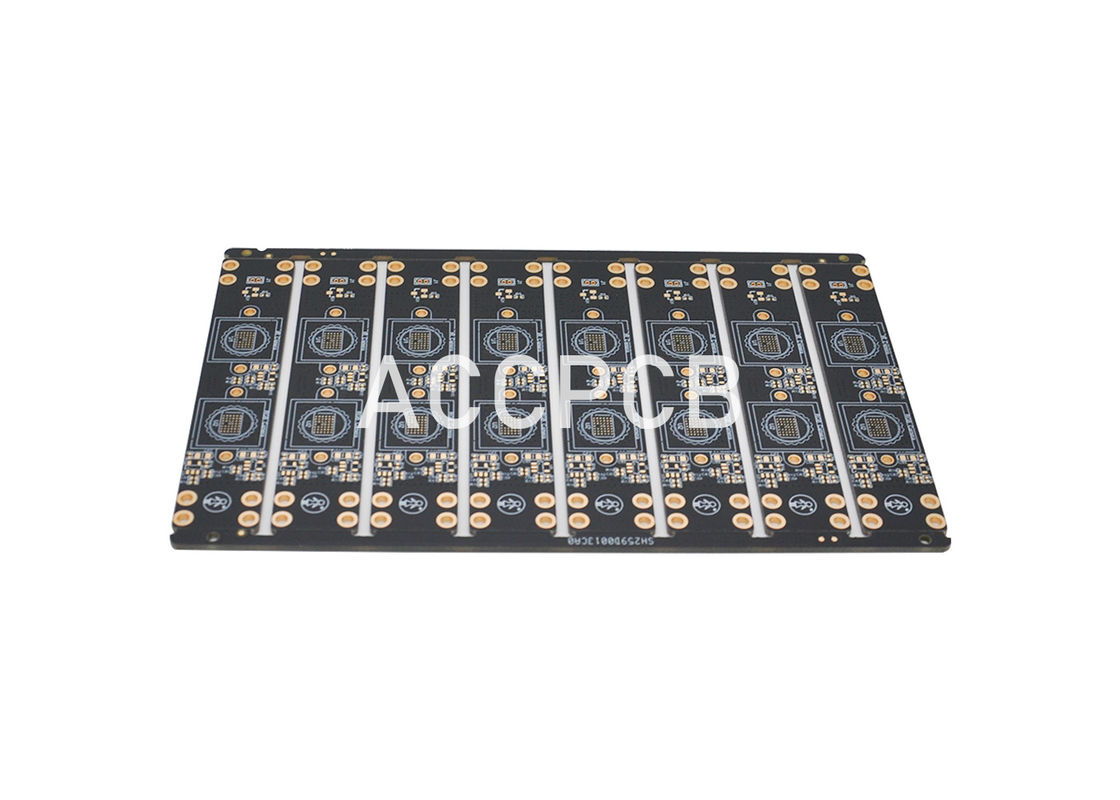

Blank Copper PWB Board 0.25mm Thickness and Customizable Black Solder Mask

Key Specifications/Special Features:

| Material : |

Sheng yi FR4 tg150

|

| Finish thickness : |

0.25 ±10%mm

|

| Minimum width/spacing : |

0.15 / 0.15mm |

| Minimum via dia : |

0.25mm |

| Surface finish : |

Immersion gold

|

| Application : |

printer machines

|

| Solder mask : |

Black |

| Legends : |

White |

Advantages:

• Strict product liability, taking IPC-A-160 standard

• Engineering pretreatment before production

• Production process control (5Ms)

• 100% E-test, 100% visual inspection, including IQC, IPQC, FQC, OQC

• 100% AOI inspection, including X-ray, 3D microscope and ICT

• High-voltage test, impedance control test

• Micro section, soldering capacity, thermal stress test, shocking test

• In-house PCB production

• No minimum order quantity and free sample

• Focus on low to medium volume production

• Quick and on-time delivery

Main Export Markets:

- Asia

- Australasia

- Central/South America

- Eastern Europe

- Mid East/Africa

- North America

- Western Europe

Shipping Information :

FOB Port : Hong Kong / Shenzhen

Lead Time : 6-10 days

HTS Code : 8534.00.10

Dimensions Per Carton : 37X27X22 cm

Weight Per Carton : 20 Kilograms

FAQ :

1. What kinds of boards can ACCPCB process?

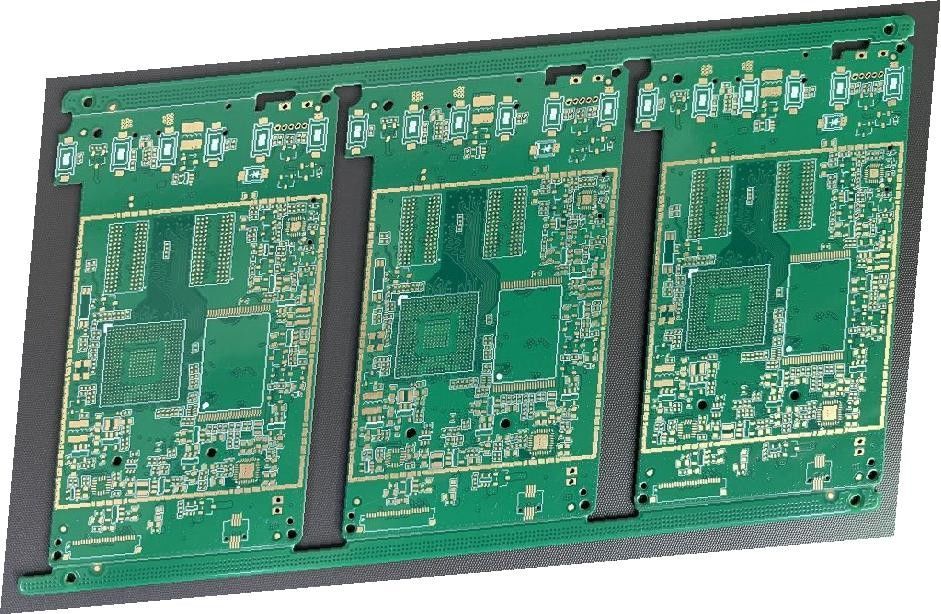

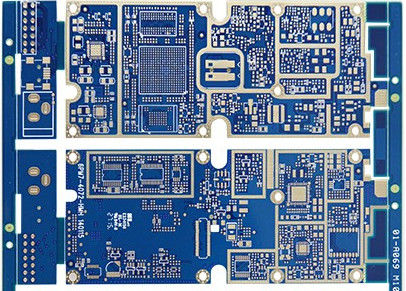

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

2. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

3. How many types of surface finish ACCPCB can do?

the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

4. What are the main factors which will affect the price of PCB?

Material;

Surface finish;

Board thickness, Copper thickness;

Technology difficulty;

Different quality criteria;

PCB characteristics;

Payment terms;

5. How to you make the impedance calculation?

The impedance control system is done using some test coupons, the SI6000 soft and the CITS 500s equipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!