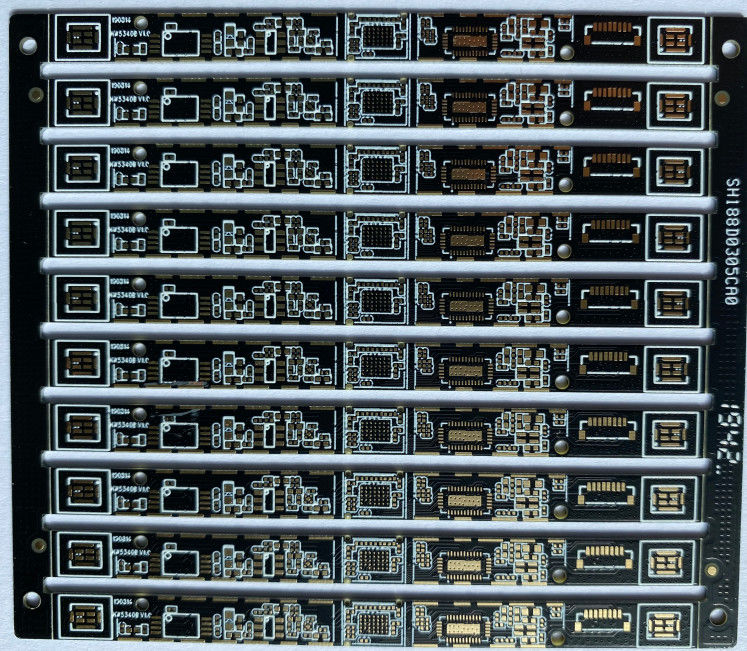

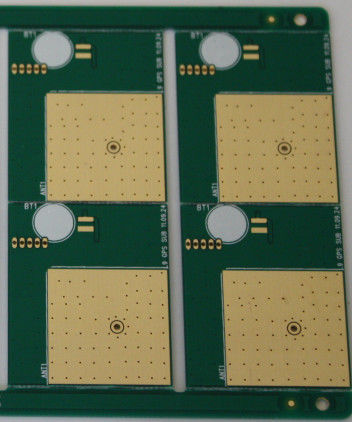

PWB PCB Board 1.20mm thickness with UL ROHS SGS Certification For LED lighting

Production description :

this board is double sided layer. it is use for LED lighting. all of our PCB boards are met UL, TS 16949,ROHS, ISO Etc. certification. no MOQ request for new order.

Key Specifications/Special Features:

| Layer count: |

2layer |

| Material : |

FR4 |

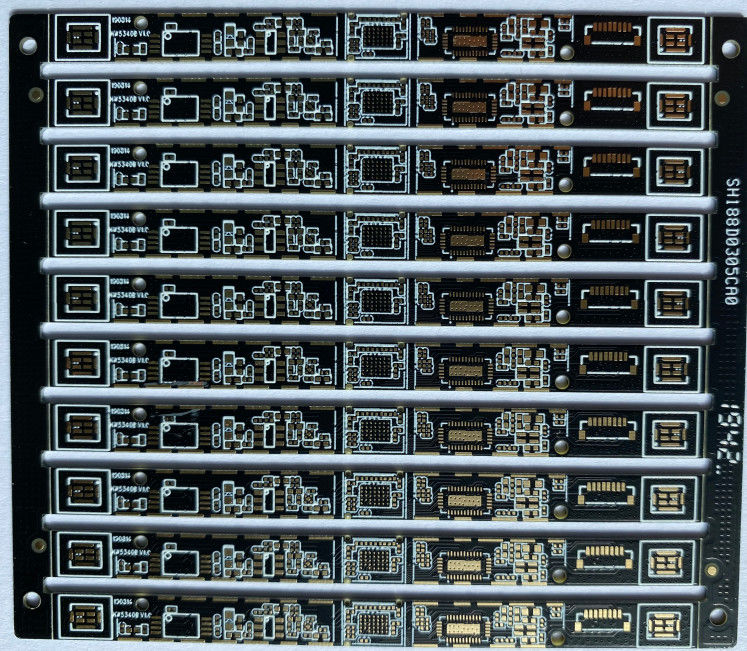

| Finish thickness : |

1.2±10%mm

|

| Board Size : |

120.00X30.00mm |

| Minimum width/spacing : |

0.127 / 0.127mm

|

| Minimum via dia : |

0.25 mm

|

| Surface finish : |

Immersion gold |

| Solder mask : |

Black

|

| Legends : |

white |

| Certification : |

UL ROHS SGS |

| Working panel size : |

max:1200mmX600mm (47'' X24'') |

| Outline profile: |

Punching, Routing , CNC routing + V-cut |

| Solder mask : |

LPI Solder mask, Peelable mask |

| Certificate : |

UL, CQC, TS16949, ISO14000, ROHS |

| Twist and Bow : |

no more than 0.75 % |

PCB Flow Chart.pdf

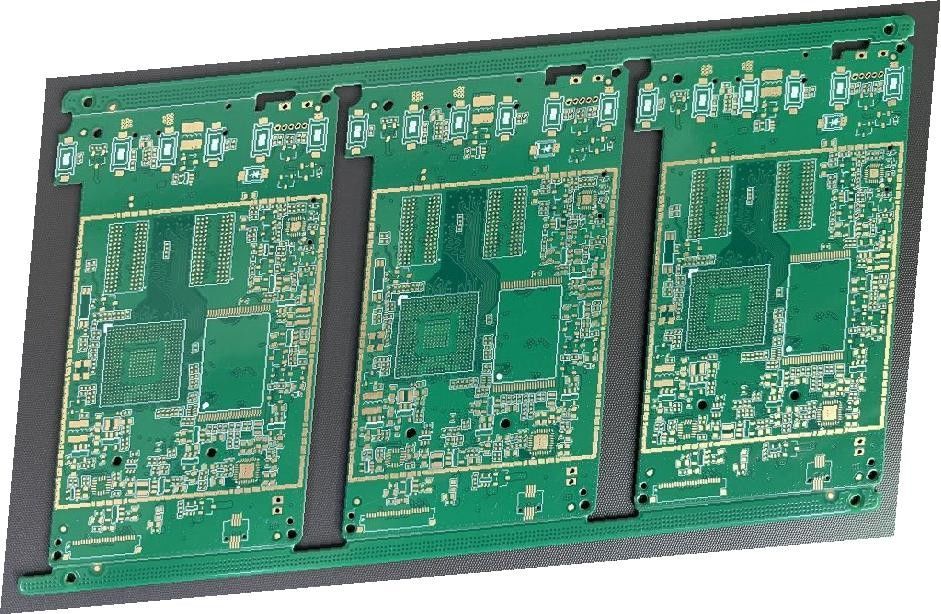

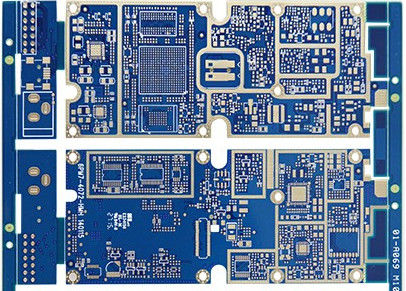

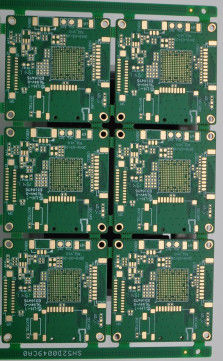

Here is our PCB order capability:

- Layer : up to 20 layers

- Materials : FR-4, FR4 High Tg/ High CTI Material

- TG : 130-170

- Surface : HASL LF , Immersion Gold/Silver/Tin, OSP, Gold Plated

- Min drill size : 0.10mm

- Min track/spacing : 4/4-mil

- Buried and blind via : 0.2mm

- CNC Milling and V-cut

- Solder mask colors : Green, Blue, Black, White, Red and Yellow, Matte green, Matte black, Matte Blue

- Silkscreen colors : black, white and yellow

- Half Holes

- Impedance control

- Blue Peelable Mask

- Carbon Treated

- HDI available

Shipping Information :

FOB Port : Hong Kong / Shenzhen

Lead Time : 6-10 days

HTS Code : 8534.00.10

Dimensions Per Carton : 37X27X22 cm

Weight Per Carton : 20 Kilograms

FAQ :

1. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

2. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

3. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

4. How many types of surface finish ACCPCB can do?

the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

6. What are the main factors which will affect the price of PCB?

Material;

Surface finish;

Board thickness, Copper thickness;

Technology difficulty;

Different quality criteria;

PCB characteristics;

Payment terms;

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!