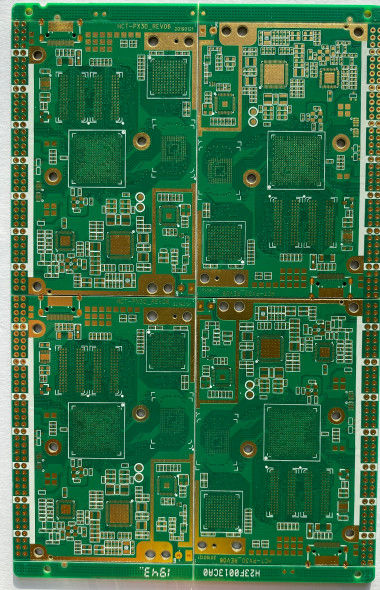

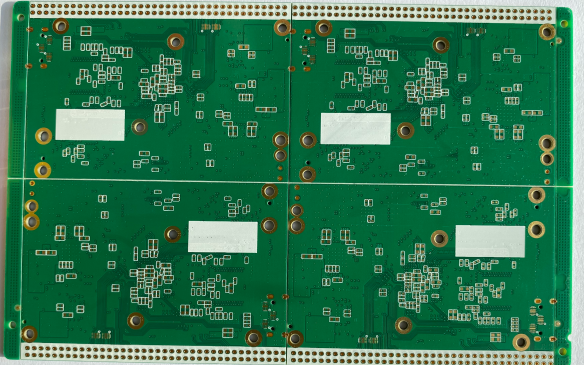

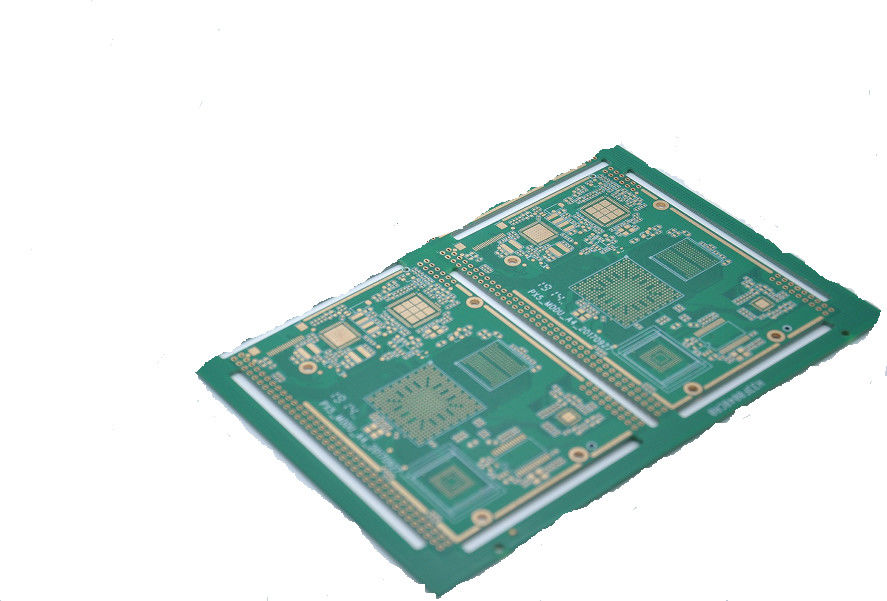

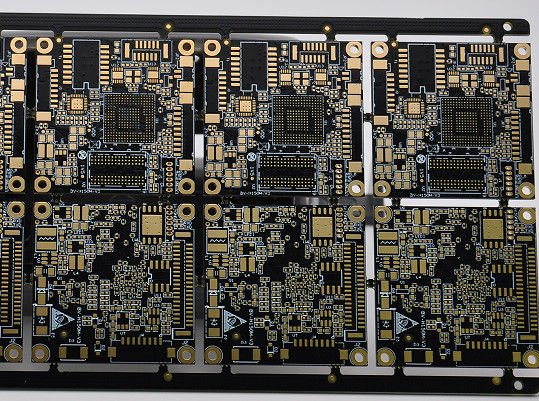

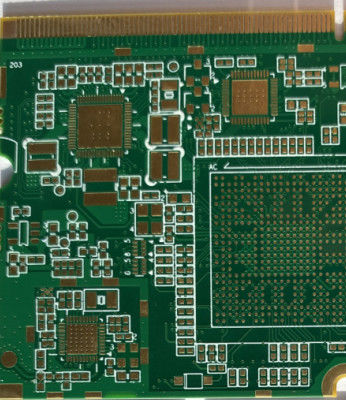

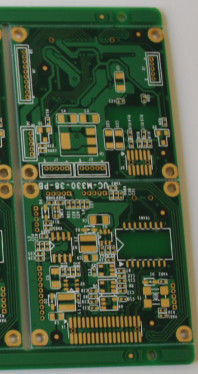

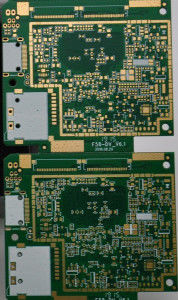

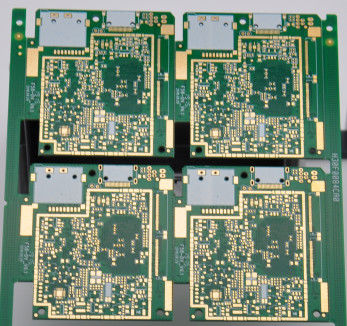

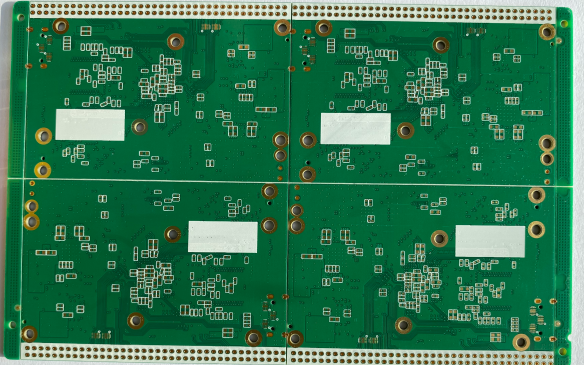

8 Layer High Density Interconnect PCB Green Solder Mask with Immersion gold sureface

Production description :

this board is 8L PCB. it is used for aerospace production. all of PCB are passed ISO9001,ROHS, UL, TS16949 certifacaion etc.

Key Specifications of tablet PCB board :

| Production Types: |

Rigid PCB |

| Layer : |

8 layer |

| Base Material : |

FR4150 |

| Copper Thickness : |

2oz |

| Board Thickness : |

1.6mm |

| Min. Finish Hole Size : |

8 mil (0.20mm) |

| Min. Line Width : |

4 mil |

| Min. Line Spacing : |

4 mil |

| Surface Finishing : |

ENIG,OSP,HASL lead free ,Immersion Gold,Gold Plating |

| Drilling hole tolerance: |

+/-3 mil ( 0.075mm ) |

| Min Outline tolerance : |

+/-4 mil ( 0.10mm ) |

| Working panel size : |

max:1200mmX600mm (47'' X24'') |

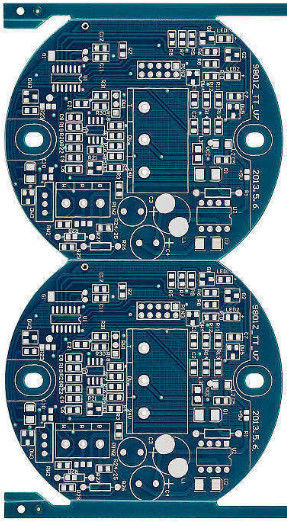

| Outline profile: |

Punching, Routing , CNC routing + V-cut |

| Solder mask : |

LPI Solder mask, Peelable mask |

| Solder Mask Color : |

Blue, black,yellow, matte green |

| Certificate : |

UL, CQC, TS16949, ISO14000, ROHS |

| Silkscreen color : |

White |

| Twist and Bow : |

no more than 0.75 % |

PCB Flow Chart.pdf

ACCPCB Technical Capability.pdf

Lead Time:

| Types |

(Max ㎡/month)

|

Samples

(days)

|

Mass Production(days) |

| New PO |

Repeat PO |

Urgent |

| 2layer |

50000 sq.m/month |

2-3 |

10-11 |

8-9 |

4 |

| 4layer |

5-6 |

11-12 |

9-11 |

5 |

| 6layer |

6-7 |

13-14 |

12-14 |

6 |

| 8layer |

7-8 |

16-18 |

14-15 |

7 |

• Strict product liability, taking IPC-A-160 standard

• Engineering pretreatment before production

• Production process control (5Ms)

• 100% E-test, 100% visual inspection, including IQC, IPQC, FQC, OQC

• 100% AOI inspection, including X-ray, 3D microscope and ICT

• High-voltage test, impedance control test

• Micro section, soldering capacity, thermal stress test, shocking test

• In-house PCB production

• No minimum order quantity and free sample

• Focus on low to medium volume production

• Quick and on-time delivery

FAQ :

1. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

2. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

3. How many types of surface finish ACCPCB can do?

the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

4. What are the main factors which will affect the price of PCB?

Material;

Surface finish;

Board thickness, Copper thickness;

Technology difficulty;

Different quality criteria;

PCB characteristics;

Payment terms;

5. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!