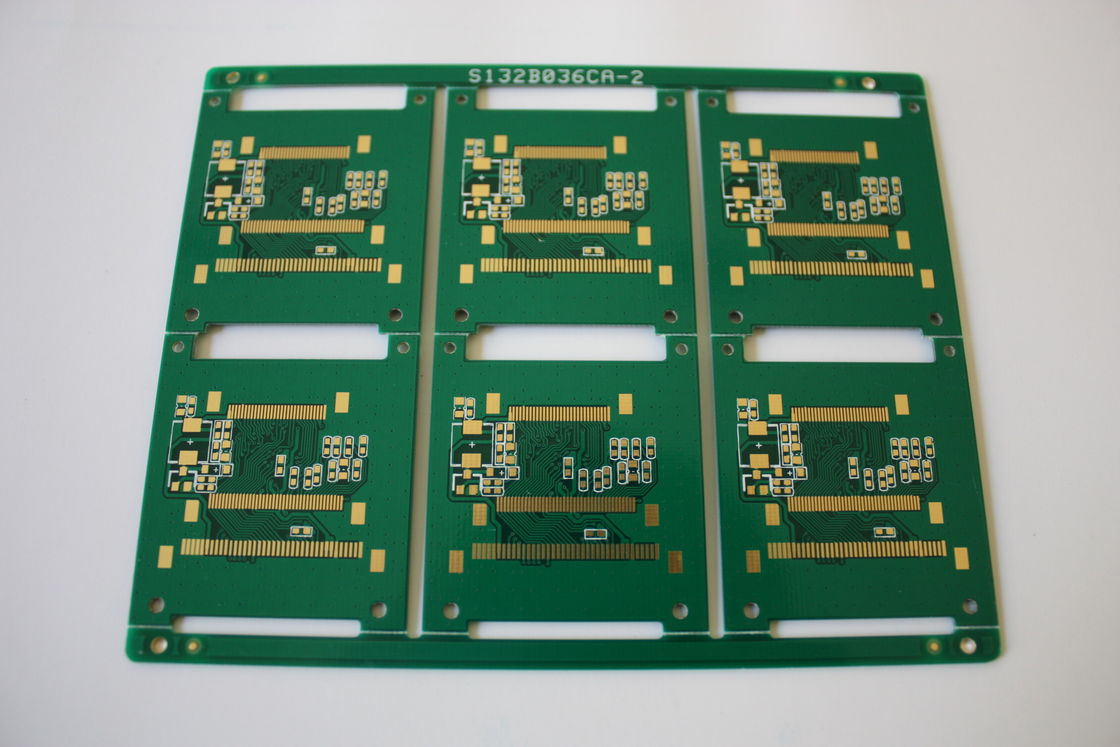

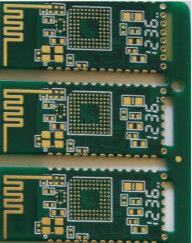

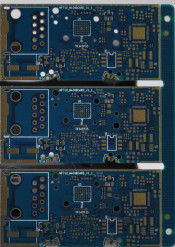

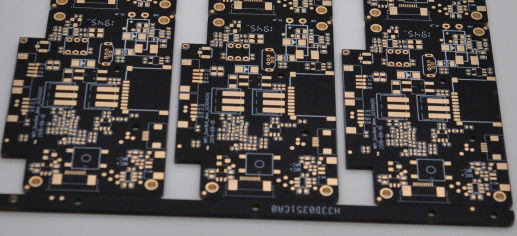

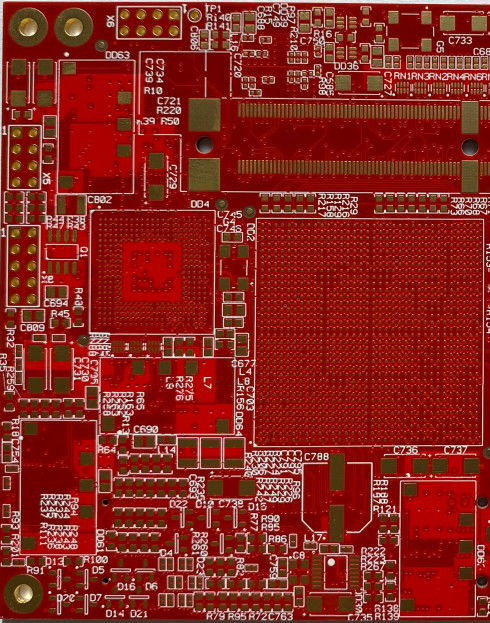

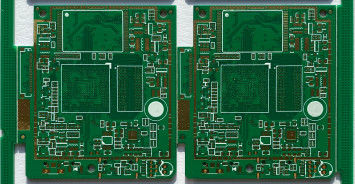

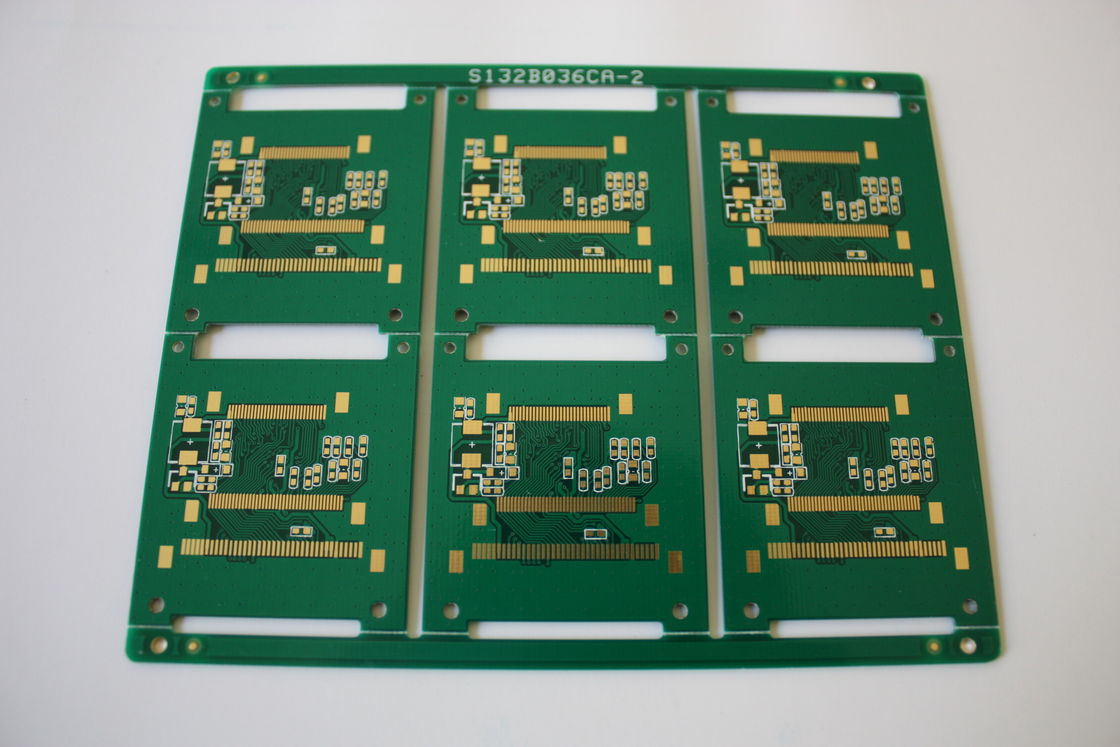

OEM 94v0 Impedance Control PCB 20um of Holes Copper 8layer 1.20mm thickness

Key Specifications/Special Features :

| Base Material : |

KB FR4 |

| Board Thickness : |

1.58 mm |

| Layers : |

8 layers |

| Copper thickness : |

1.2 OZ In all layer |

| Surface Finish : |

Immersion gold |

| Copper Thickness in Hole : |

min 20um |

| Impedance : |

100Ohm |

| Min. Hole Size : |

0.20mm |

| Min. Line Width : |

0.1mm/4mil |

| Min. Line Spacing : |

4/4mil(0.1/0.1mm) |

Quality assurance :

Every production process has a special person to test to ensure quality, AOI, E-testing, Flying Probe Test.

Have professional engineers to check the quality

All products have passed CE, FCC, ROHS and other certifications

Application:

Widely used in stage, Industrila control,computer,consuming electronics,security,automotive,power electronics,medical,telecom etc.

Lead Time :

| Lead Time |

2 /L |

4 /L |

6/ L |

8/ L |

| Sample Order |

3-5days |

6-8days |

10-12days |

12-14days |

| Mass Production |

7-9days |

8-10days |

12-15days |

15-18days |

FAQ :

1. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

2. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

3. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

4. What’s the typical process flow for multi-layer PCB?

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond→ Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!