PCB Flow Chart.pdf

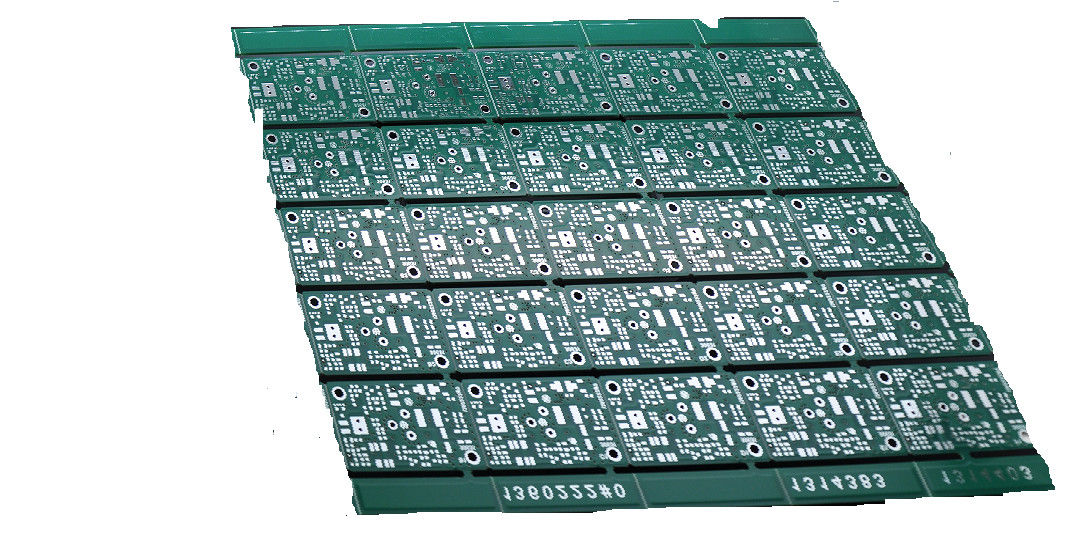

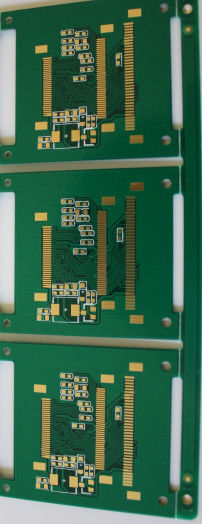

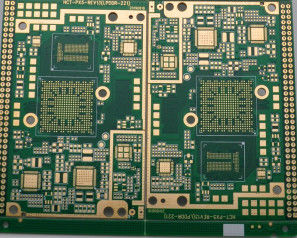

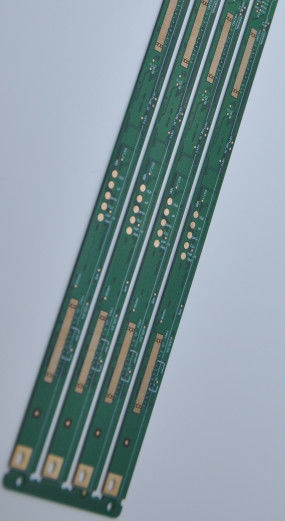

Rigid PCB Technical Capability:

|

Items

|

Technical Capability

|

|

Layers

|

1-28 layers

|

Min. line width/space

|

4mil

|

|

Max.board size (single&doule

sided)

|

600*1200mm

|

Min.annular ring width: vias

|

3mil

|

|

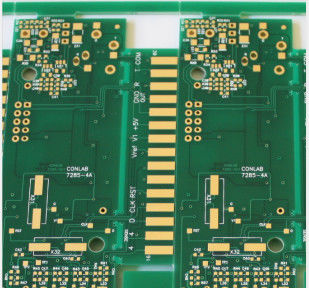

Surface finish

|

HAL lead free,gold flash

Immersion silver,Immersion gold ,Immersion Sn,

hard gold,OSP,ect

|

Min.board thickness(multilayer)

|

4layers:0.4mm;

6layers:0.6mm;

8layers:1.0mm;

10layers:1.20mm

|

|

Board materials

|

FR-4; high Tg; high CTI; halogen free; high frequency(rogers,taconic,

PTFE,nelcon,

ISOLA,polyclad 370 HR); heavy copper,

Metal base clade laminate

|

Plating thickness (Technique:

Immersion Ni/Au)

|

Plating type: Imm Ni, Min./Max thickness:100/150U'' Plating type: Imm Au, Min./Max thickness:2/4U''

|

|

Impedance control

|

± 10%

|

Distance between

line to board edge

|

Outline: 0.2mm

V-CUT: 0.4mm

|

|

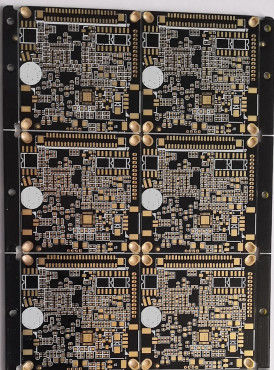

Base copper thickness(Inner

and outer layer)

|

Min. thickness: 0.5 OZ Max.thickness: 6OZ

|

Min.hole size(board thickness ≥2mm)

|

Aspect ratio≤16

|

|

Finished copper thickness

|

Outer layers:

Min.thickness 1 OZ,

Max.thickness 10 OZ

Inner layers:

Min.thickness :0.5OZ,

Max.thickness : 6 OZ

|

Max.board thickness(single&doule sided)

|

3.20mm

|

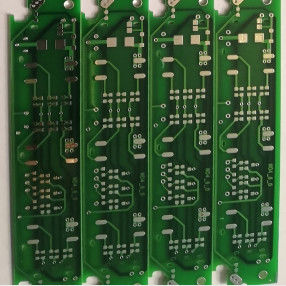

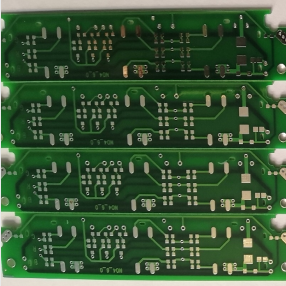

Products Application:

1, Consumer Electronics: TV, DVD,Digital Caramer, air conditoner, Refrigerator,set-top box etc;

2, Security monitor: Moible phone, PDA, GPS, caramer monitor etc;

3, Telecom Communication :wireless LAN card, XDSL router,Servers, Optical Device,Hard Drive etc;

4, Industrial controls: Medical device ,UPS equipment, Control device etc;

5, Vehicle Electronices: Car etc;

6, Military & Defense : Military Weapons etc;

FAQ:

1. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

2. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

3. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

4. What’s the typical process flow for multi-layer PCB?

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond→ Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!