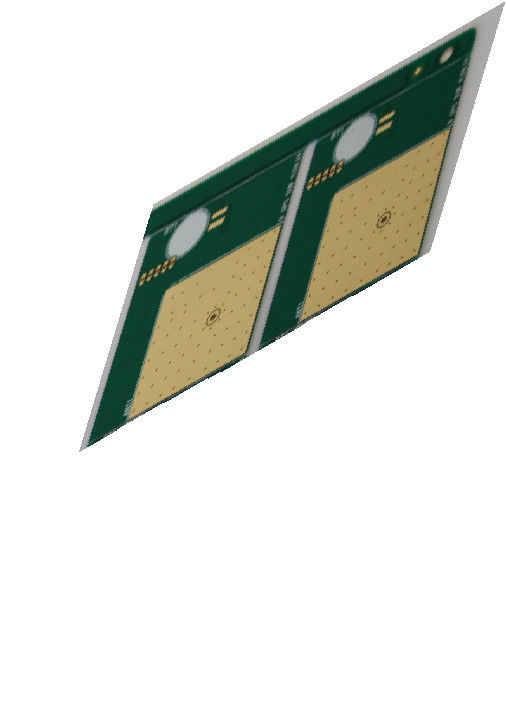

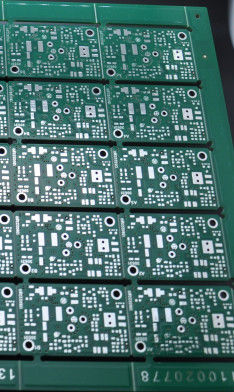

94v0 Prototype PCB Fabrication 6 Mil Minimum Hole Size for Game Driver Applied

Production description :

this board is 4layer PCB it is used on game driver. PCB prototype,samll volum, middle and large volume are accepted. no MOQ request for new boards.

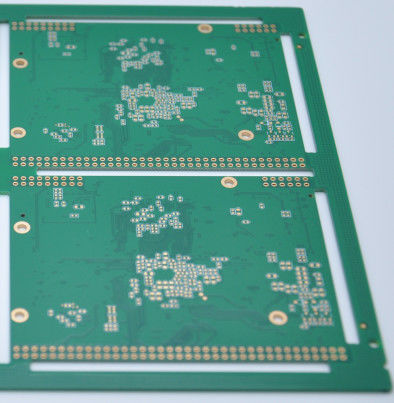

Production Feature:

| Layer : |

4 Layers |

| Base Material : |

FR4 |

| Copper Thickness : |

0.5oz inner Layer, 1oz out layer |

| Board Thickness : |

1.50 mm |

| Surface Finish : |

Lead free HAL |

| Min. Hole Size : |

6 mil / 0.15mm |

| Min. Line Width : |

4/4 mil / 0.10/0.10 mm |

| Min. Line Spacing : |

4/4mil / 0.10/0.10mm |

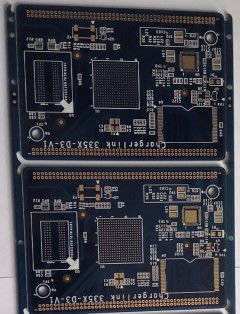

| Application : |

Game Driver |

| Certification : |

ISO9001, UL, ROHS,TS16949 |

| Drilling hole tolerance: |

+/-3 mil ( 0.075mm ) |

| Min Outline tolerance : |

+/-4 mil ( 0.10mm ) |

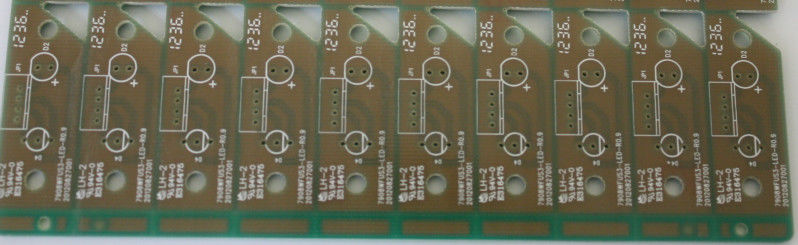

| Working panel size : |

max:1200mmX600mm (47'' X24'') |

| Outline profile: |

Punching, Routing , CNC routing + V-cut |

| Solder mask : |

LPI Solder mask, Peelable mask |

PCB Flow Chart.pdf

Products Application:

Our products are widely used in meter, medical, solar energy, mobile, communication, industrial control, power electronics,security, consuming, computer, automotive, aerospace, military and so on.

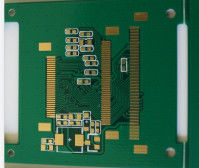

Rigid PCB Technical Capability:

| Items |

Technical Capability |

| Layers |

1-28 layers |

Min. line width/space |

4mil |

|

Max.board size (single&doule

sided)

|

600*1200mm |

Min.annular ring width: vias |

3mil |

| Surface finish |

HAL lead free,gold flash

Immersion silver,Immersion gold ,Immersion Sn,

hard gold,OSP,ect

|

Min.board thickness(multilayer) |

4layers:0.4mm;

6layers:0.6mm;

8layers:1.0mm;

10layers:1.20mm

|

| Board materials |

FR-4; high Tg; high CTI; halogen free; high frequency(rogers,taconic,

PTFE,nelcon,

ISOLA,polyclad 370 HR); heavy copper,

Metal base clade laminate

|

Plating thickness (Technique:

Immersion Ni/Au)

|

Plating type: Imm Ni, Min./Max thickness:100/150U'' Plating type: Imm Au, Min./Max thickness:2/4U'' |

| Impedance control |

± 10% |

Distance between

line to board edge

|

Outline: 0.2mm

V-CUT: 0.4mm

|

|

Base copper thickness(Inner

and outer layer)

|

Min. thickness: 0.5 OZ Max.thickness: 6OZ |

Min.hole size(board thickness ≥2mm) |

Aspect ratio≤16 |

| Finished copper thickness |

Outer layers:

Min.thickness 1 OZ,

Max.thickness 10 OZ

Inner layers:

Min.thickness :0.5OZ,

Max.thickness : 6 OZ

|

Max.board thickness(single&doule sided) |

3.20mm |

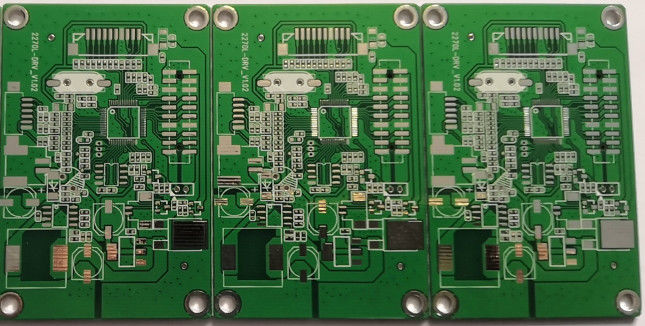

Advantages:

• Strict product liability, taking IPC-A-160 standard

• Engineering pretreatment before production

• Production process control (5Ms)

• 100% E-test, 100% visual inspection, including IQC, IPQC, FQC, OQC

• 100% AOI inspection, including X-ray, 3D microscope and ICT

• High-voltage test, impedance control test

• Micro section, soldering capacity, thermal stress test, shocking test

• In-house PCB production

• No minimum order quantity and free sample

• Focus on low to medium volume production

• Quick and on-time delivery

Lead Time :

| Lead Time |

2 /L |

4 /L |

6/ L |

8/ L |

| Sample Order |

3-5days |

6-8days |

10-12days |

12-14days |

| Mass Production |

7-9days |

8-10days |

12-15days |

15-18days |

FAQ :

1. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

2. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

3. What’s the typical process flow for multi-layer PCB?

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond→ Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.

4. How many types of surface finish ACCPCB can do?

ACCPCB has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!