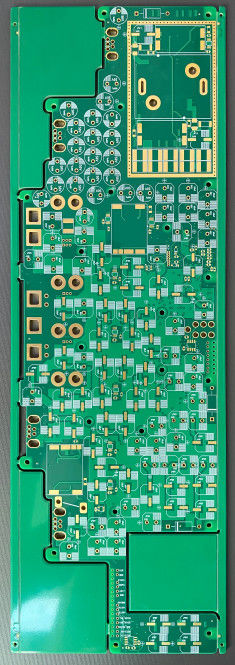

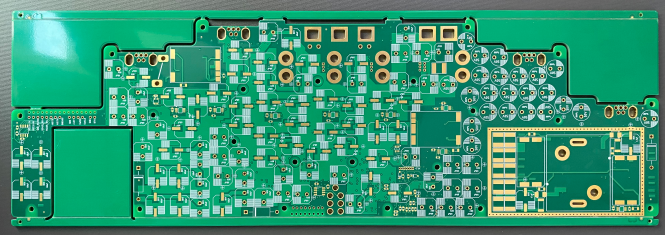

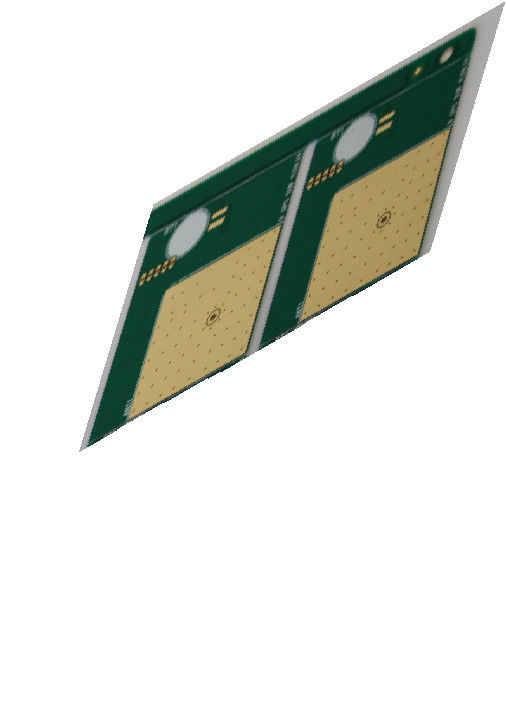

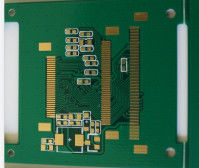

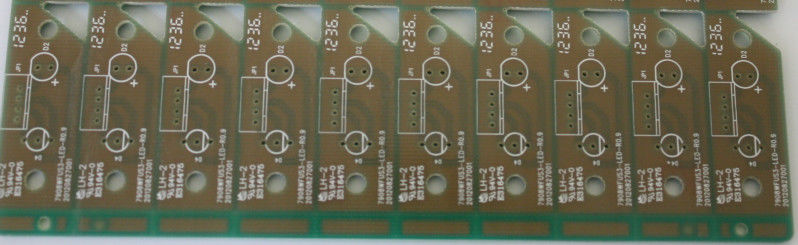

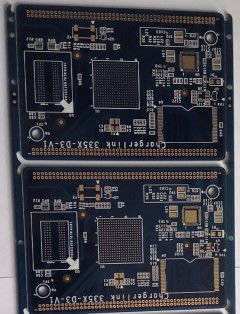

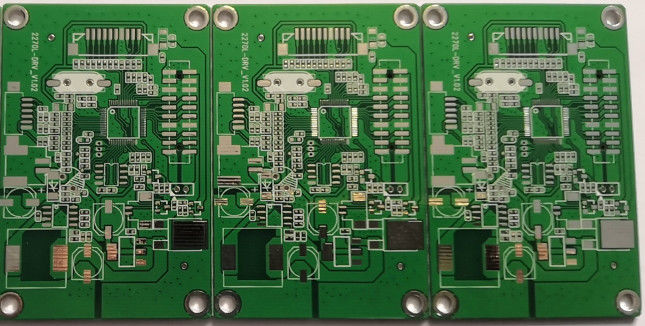

FR4TG130,1.0MM thickness Lead Free PCB 100x50MM with Green solder mask for LED car light

Production Feature:

| Layer : |

4 Layers |

| Base Material : |

FR4 tg130 |

| Copper Thickness : |

1oz in all layer |

| Board Thickness : |

1.0 mm |

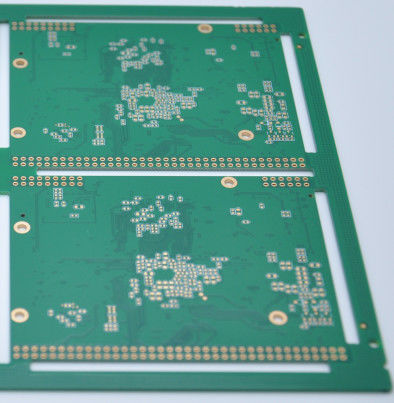

| Surface Finish : |

Immersion gold |

| Min. Hole Size : |

6 mil / 0.15mm |

| Min. Line Width : |

4mil |

| Min. Line Spacing : |

4mil |

| Certification : |

ISO9001, UL, ROHS,TS16949 |

| Company type: |

Manufacturer/ Factory |

Quality assurance :

- Every production process has a special person to test to ensure quality

- Have professional engineers to check the quality

- All products have passed CE, FCC, ROHS and other certifications

Advantages :

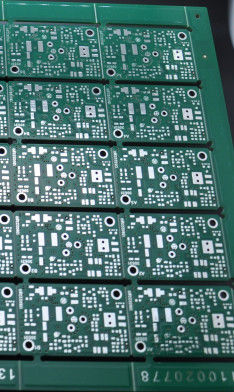

▪ No MOQ, 14 years of PCB turnkey services

▪ Quick turn, prototype, low & medium & high volume

▪ OEM services provide

▪ ISO 9001-, ISO 14001-, ISO/TS16949, ISO 13485, IATF16949, OHSAS18001 certified

▪ 100% E-test, visual, AOI inspection, including X-ray, 3D microscope

▪ Fast response within 24 hours

FAQ:

1. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

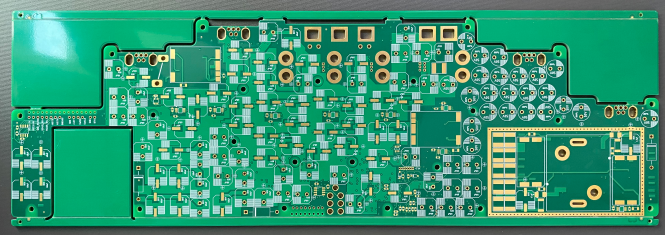

2. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

3. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

4. What’s the typical process flow for multi-layer PCB?

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond→ Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.

5. How many types of surface finish ACCPCB can do?

the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!