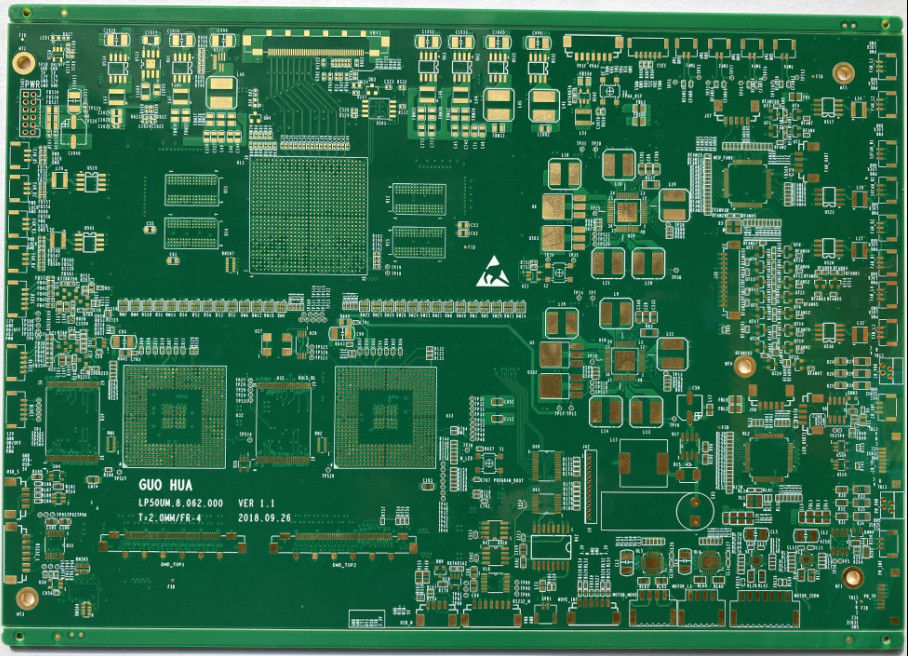

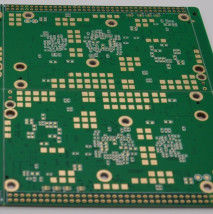

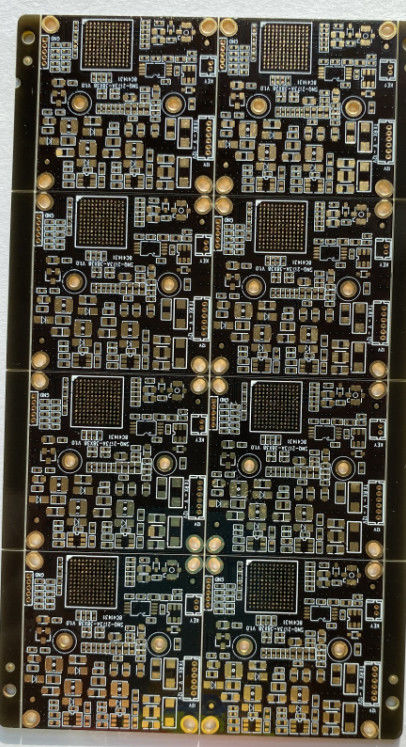

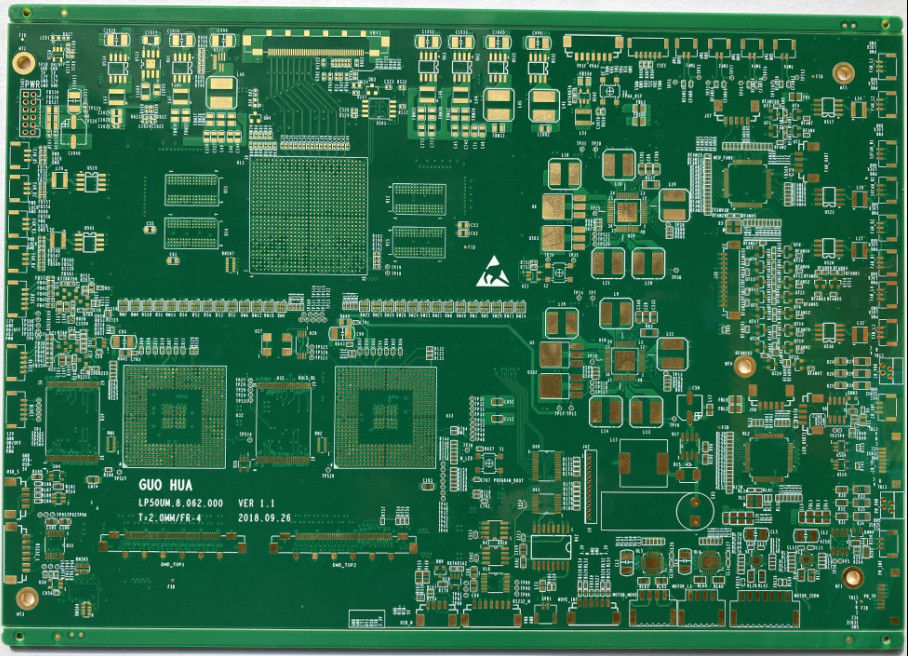

1.2mm Thickness high TG PCB with Immersion Gold Surface Finishing and 200X300mm

Key Specifications/Special Features :

| Layer : |

4Layers |

| Base Material : |

FR4TG170 |

| Copper Thickness : |

2/1/1/2oz |

| Board Thickness : |

1.20mm |

| Min. Hole Size : |

6 mil / 0.15mm |

| Min. Line Width : |

4/4 mil, 0.075/0.075 mm |

| Min. Line Spacing : |

4/4mil, 0.075/0.075 mm |

| Surface Finishing : |

HAL,ENIG,OSP |

| Solder Mask Color : |

Green ,Red,Blue,White,Yellow,Red |

| Certificate : |

UL, CQC, TS16949, ISO14000, ROHS |

| Company type : |

Manufacturer/ Factory |

| Silkscreen color : |

White,Yellow,Red,Black |

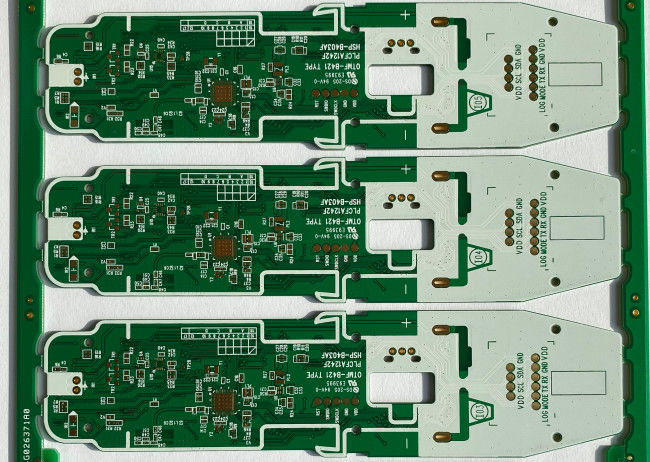

| Outline : |

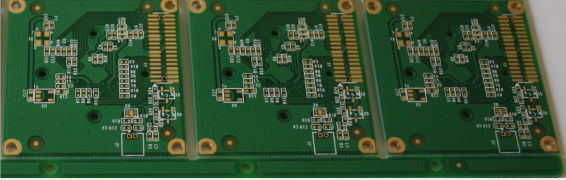

Routing,V-Groove, Beveling punch |

Quality assurance :

Every production process has a special person to test to ensure quality, AOI and E-testing.

Have professional engineers to check the quality

All products have passed CE, FCC, ROHS and other certifications

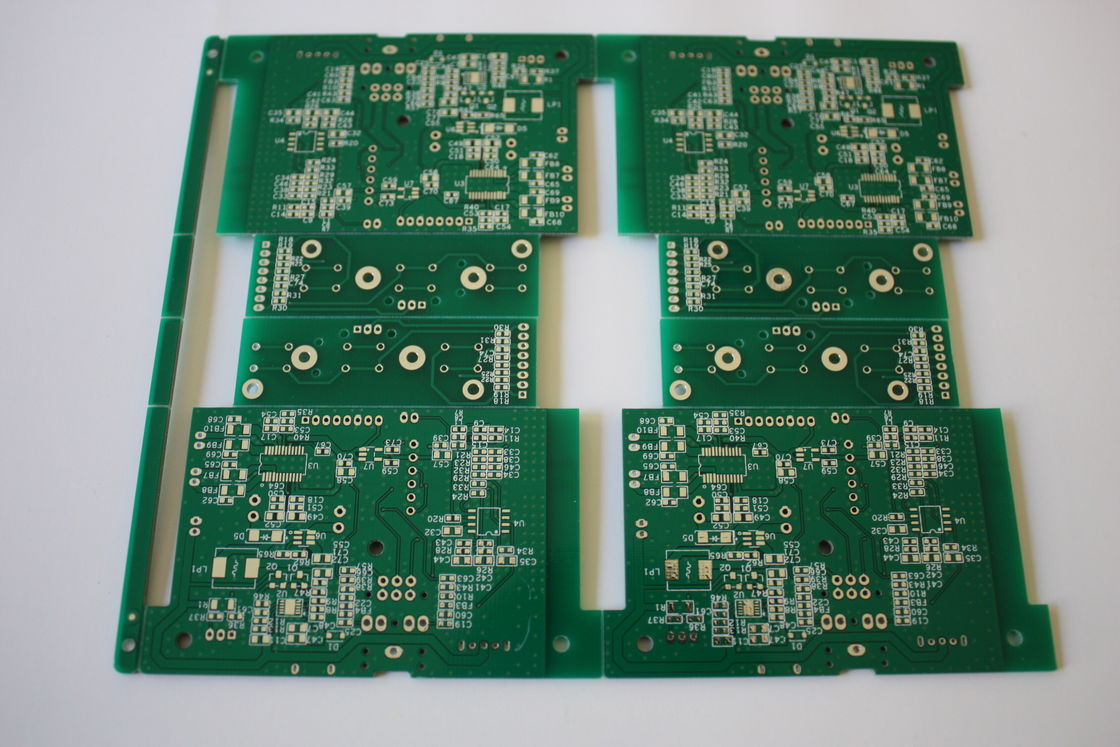

Application:

Industril Control System

Power Supply

LED drive, LED Lighting

Communication Device

automotive electronics

Security Electronics

Household Control

Digital Appliances

Frequency converter

Medical Device

FAQ :

1. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

2. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

3. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

4. What’s the typical process flow for multi-layer PCB?

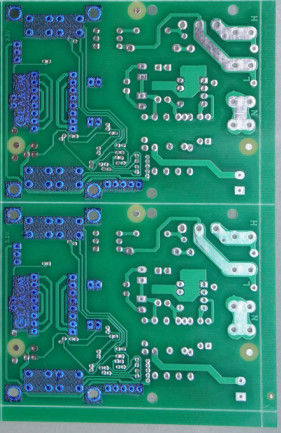

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond→ Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.

5. How many types of surface finish ACCPCB can do?

the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

6. What are the main factors which will affect the price of PCB?

Material;

Surface finish;

Board thickness, Copper thickness;

Technology difficulty;

Different quality criteria;

PCB characteristics;

Payment terms;

7. How to you make the impedance calculation?

The impedance control system is done using some test coupons, the SI6000 soft and the CITS 500s equipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!